Standards Compliant

GB/T 10006,ASTM D1894,TAPPI T816,ISO 8295,GB/T 17200

Application Field

Packaging/Food/Medicine/New material/Chemical/Printing

It is suitable for the packaging industry, the paper-making industry, film manufacturers, packaging material testing institutions, etc. to measure the static friction coefficient and dynamic friction coefficient during the sliding of materials such as plastic films, rubbers, papers, paperboard, woven bags, woods, coatings, etc. By determining the magnitude of the friction coefficient, the smoothness, the difficulty of opening, and the uniformity can be judged, so as to correctly guide production and control and adjust the production process.

Cut the sample into two pieces. Place one piece on the workbench and clamp it with the sample holder. Wrap the other piece around the slider. Then, place the slider on the hanging hole of the sensor. Make the sample move under the gravity applied to the slider, that is, make the two test surfaces move relatively. The force signal measured by the sensor is amplified by the integrator and sent to the recorder. At the same time, the dynamic friction coefficient and the static friction coefficient are recorded respectively.

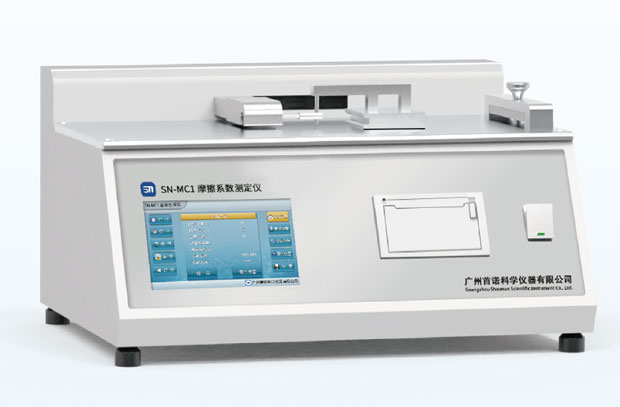

1.Stable performance and accurate test results.

2.Simple operation and thermal printing of test reports.

3.Longer service life and more perfect performance.

4.5-inch touch screen display for convenient operation.

5.Capable of saving 10 groups of data and printing them.

6.Password is required for calibration to prevent accidental modification.

|

Item

|

Parameter

|

|

Force measurement range

|

0 - 2N (customizable)

|

|

Accuracy

|

Level 0.5

|

|

Specimen thickness

|

≤2mm (customizable)

|

|

Coefficient measurement range

|

0.001 - 0.999

|

|

Slider size

|

63mm×63mm

|

|

Test speed

|

100mm/min (150mm/min optional)

|

|

Slider mass

|

200g (customizable)

|

|

Workbench size

|

200mm×470mm

|

|

Measurement error

|

±2%

|

|

Power supply

|

AC 220V/50Hz

|

|

Dimensions

|

470mm×350mm×220mm

|

|

Instrument Configuration

|

One main unit, one miniature printer, a power cord,one slider.

|

Deliver,Shipping And Serving

Provide product technical parameters, application scenarios, and other information to help you to choose the right equipment. Solution Design, sample testing, on-site visits is also supported.

Clarify details such as price, delivery time, payment methods, sign the contracts, and provide operation/ maintenance training to ensure customers use the instruments correctly.Assist customers with acceptance procedures and debugging each goods before shipment to ensure the instruments meet contract requirements.

In addition to the 1-year warranty, we also provide lifelong remote technical support to solve usage problems, provide regular maintenance services, and solve specific problems for customers in a timely manner.

Tel:13556033107

Tel:13556033107 E-mail:info@snlabtester.com

E-mail:info@snlabtester.com